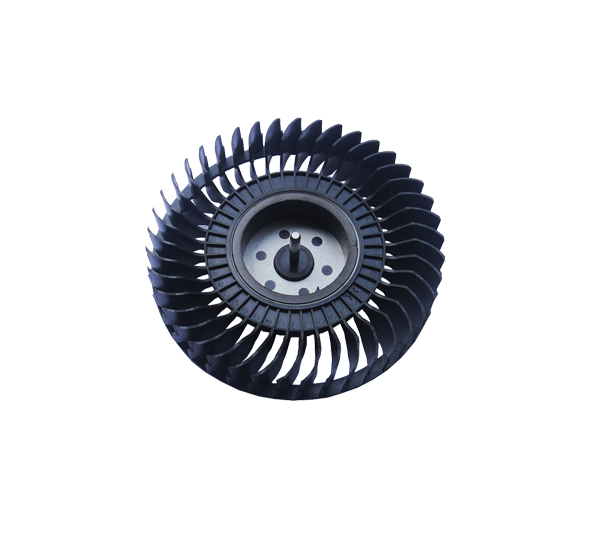

1.Magnetic stripe turntable: fill magnetic strip on feding approach riticilelly The magnetic stripe is automatically pressed into the fixture be automatically transferred to the charge head for magnetization (both inside and outside can be equipped on the machine) the charged magnetic ring is pressed into the plastic covered fan blade;

2.fan blade turntable: put the fan blade manually onto the assembly line - loading robot clamps to the positioning station (CCD photos for spotting) - loading robot clamps to the turntable be automatically transferred to the dispensing station be automatically transferred to the fan station to press into the magnetic stripe - automatically transferred to the cutting station, mechanical folder discharge (finished products automatically exit,docking with production line).

3.The process of pressing the magnetic stripe into the blade is controlled by the servo motor and the screw rod, the height adjustable.

4.Fixture replaceable for blades of different sizes.

5.Discharge time and voltage can be arbitrarily set on the automatic machine.

0755-2813 2790

0755-2813 2790

CHINESE

CHINESE