1.The device adopts micro computer program control system, and is consisted by the keyparts such as Panasonic servo motor, ball screw and stepping motor;

2.The servo motor adopted by this device has a 30% higher efficiency compare with the common AC electromotor. And it is precise in positioning, fast in acceleration anddeceleration;!

3.The winding speed is controlled by the controller, and winding, displacement, dislocation,center tapping, positioning, stopping and automatically clipping and shearing wires are all automatically finished according to the setup program;

4.High winding speed, correct circles, orderly displacement, correct positioning, automatic clipping and shearing to reduce the materials' wastage and improve the product quality aswell as production efficiency.

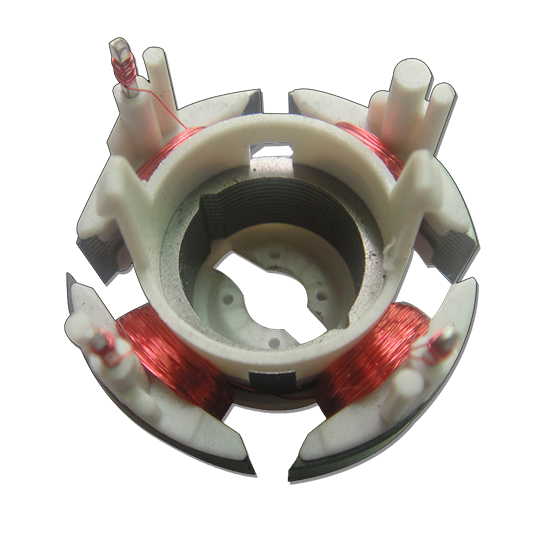

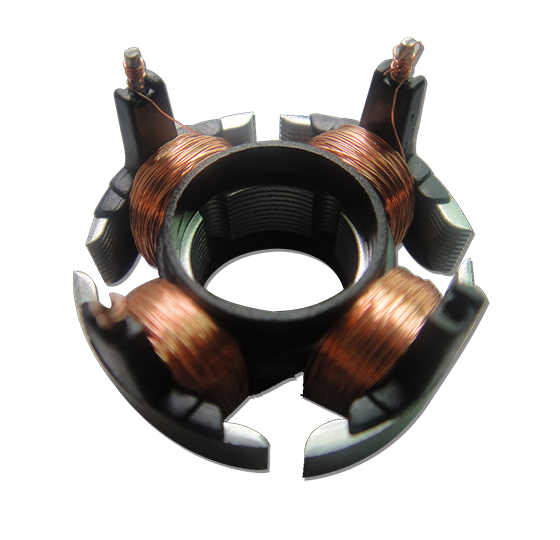

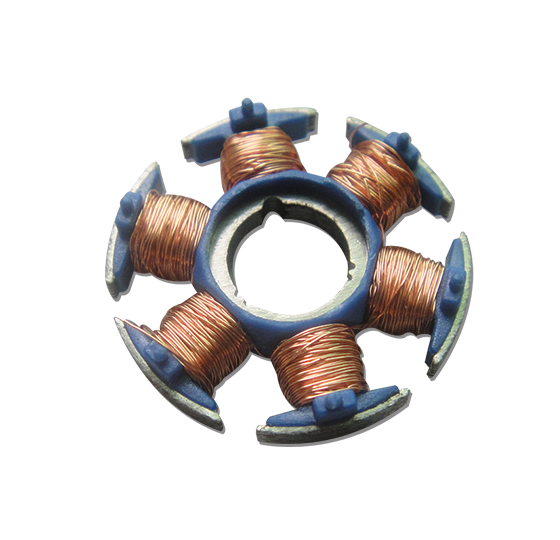

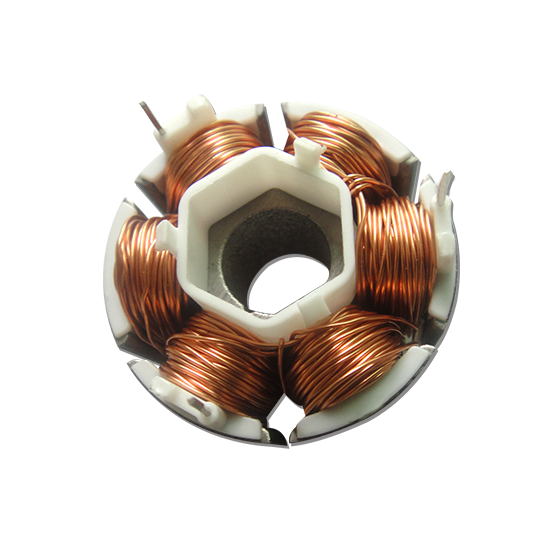

5.The winding baffle device is equipped in this machine,for the winding precision of multipie poles stator, the coil could be more flat and neat in displacement with the use of baffle winding machine.

6.The device adopts total aluminum alloy rack, elegant in shape and convenient in move.Protection device and photoelectric protection sensor are added to fully improve theoperator's safety.

0755-2813 2790

0755-2813 2790

CHINESE

CHINESE